A sensor processing circuit specifically designed for thermoresistor PT1000.

Release time:

2024-01-11

With the development of the Internet of Things era, sensors, as an important component

1. Overview

With the development of the Internet of Things era, sensors, as an important component, have broad development prospects and play an increasingly important role in various industries. Temperature sensors, as devices for measuring temperature, are widely used in fields such as ships, weapons, and aerospace. With the continuous advancement of industrial automation, the requirements for temperature control and detection are also increasing. Accurate temperature detection can monitor the application status of instruments and equipment in real-time for precise adjustment, effectively improving energy utilization efficiency and reducing energy consumption.

Platinum resistance temperature sensors made from corrosion-resistant and chemically stable platinum materials have characteristics such as high precision, good stability, good linearity, wide measurement range, high sensitivity, and high reliability. They can work stably and reliably in harsh environments to perform high-precision measurements with low distortion. Platinum resistance sensors can be widely applied in high-precision devices such as medical equipment, motors, industry, temperature calculations, satellites, meteorology, and resistance calculations. The naming convention for platinum resistance typically uses its standard resistance value at 0°C; for example, a typical platinum resistance PT1000 means that at an ambient temperature of 0°C, the typical resistance value is 1000Ω. In product application fields, a three-wire connection method is usually adopted. Compared to ordinary two-wire connections, three-wire connections have better ability to resist interference from resistive line introductions and can improve measurement accuracy.

Huangjing Company has launched a new circuit HJPT1000 specifically designed for three-wire PT1000 temperature measurement collection processing based on current development trends and market supply demands. It can convert the resistance values of PT1000 under different temperature environments into corresponding current output values. HJPT1000 is designed according to GJB2438B requirements using thick film integrated technology with F14-02 ceramic surface mount packaging specifically for measuring platinum resistance PT1000. It can be customized according to customer requirements for measurement temperature ranges. It has a built-in high-precision current source to provide current excitation for the PT1000 thermoresistor; this form of current signal excitation ensures sufficient anti-interference capability within a certain length of input connection wire which improves the collection accuracy of thermoresistors. The device HJPT1000 features high precision, low power consumption, two-wire current output with a wide power supply range that meets direct aviation voltage power supply requirements; its current output characteristics also give it strong long-line transmission capabilities and noise interference immunity while being able to withstand extreme environmental stress and harsh electromagnetic conditions.

Compatible with three-wire RTD collection processing; capable of achieving two-wire 4~20mA current output.

Power supply voltage meets direct power supply requirements of 18~36V; capable of long-line output with strong anti-interference capability.

2. Electrical Principle Block Diagram

3. Packaging Form and Terminal Functions

1. Packaging Form

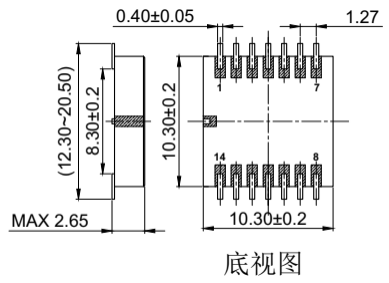

Figure 2 F14-02 Shell Size Diagram

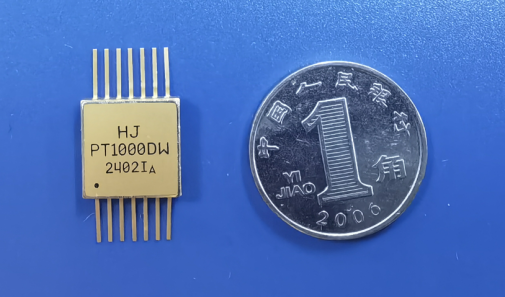

Figure 3 HJPT1000 Physical Object Comparison Diagram

2. Terminal Functions

Table 2 Packaging Terminal Function Table

|

Pin Number |

Symbol |

Function |

Pin Number |

Symbol |

Function |

|

1 |

IREF |

基准电流输出端 |

14 |

+VS |

+ Power Supply |

|

2 |

RSET2 |

基准电流设置端 |

13 |

NC |

空脚 |

|

3 |

NC |

空脚 |

12 |

IOUT |

Current Output Terminal |

|

FGND |

Floating Ground |

RSET1 |

Resistance Setting Terminal |

IN |

Signal Input |

|

TP2 |

Output Current Setting Point2 |

TP1 |

Output Current Setting Point1 |

BYPASS |

Compensation Capacitor Setting |

|

4.Electrical Characteristics |

NC |

空脚 |

Unless otherwise specified, |

+V |

=+28V,T |

|

=25℃ |

NC |

空脚 |

8 |

BYPASS |

补偿电容设置 |

四、电特性

除非另有说明,+VS=+28V,TA=25℃

表3 电特性表

|

参数名称 |

Symbol |

测试条件 |

规范值 |

单位 |

|||

|

最小值 |

典型值 |

最大值 |

|||||

|

输出低端电流 |

IOL |

|

3.9 |

FGND |

4.1 |

mA |

|

|

Output high-end current |

IOH |

|

19.5 |

20 |

20.5 |

mA |

|

|

Output current |

αIset |

Iset =4 mA |

|

70 |

100 |

ppm/℃ |

|

|

Non-linearity* |

|

|

|

0.5 |

1 |

% |

|

|

Power supply current |

IS |

VIN=0V |

|

|

2 |

2.5 |

mA |

|

-55℃~+125℃ |

|

2.6 |

3.3 |

||||

|

Power supply voltage range |

+VS |

|

18 |

|

36 |

V |

|

Note: Parameters marked with * are design guarantees.

V. Typical Application Diagram

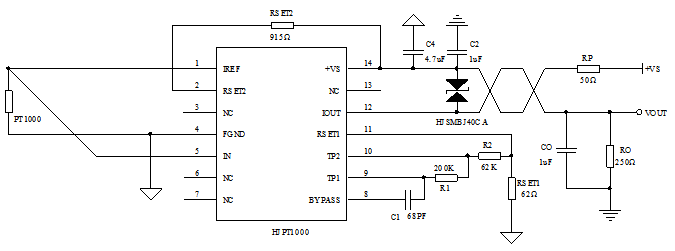

Figure4 HJPT1000 three-wire system typical application diagram

Note:

1. Note that pin FGND of HJPT1000 is the floating ground of the entire system, not the ground of power supply voltage +VS, and the current output IOUT should connect to the sampling resistor against the ground of power supply voltage.

2. Resistors R1, R2, RSET1, and RSET2 should be selected with a precision of ±0.1% to meet the overall system acquisition accuracy; peripheral components in the figure should meet parameters so that the thermistor can output from -55℃ to +200℃ in an environment temperature range of outputting from4 to20mA.

3. In high-end current applications such as a20mA output, the thermal power consumption of the entire device will become higher; a resistor RP can be added between an external positive power source and pin14 to reduce pressure difference on the device and decrease power consumption. However, care must be taken that resistance values cannot be too large; if too large, it will reduce pressure difference between collector and emitter inside transistors causing them to operate in saturation state where output current will vary with changes in power supply voltage and cannot remain stable.

4. When collecting output current after long line transmission, it is recommended that customers refer to typical application diagrams and connect a capacitor CO of1μF in parallel on terminal resistor RO; this capacitor can effectively reduce interference from industrial frequency signals smoothing out current signal outputs. Note that larger capacitance values will result in lower noise for output current signals but also increase τ value for network formed by RO and CO leading to longer establishment time for output signals; users should reasonably select capacitance based on their own signal noise requirements and establishment time needs during actual device applications.

5. Due to limitations imposed by junction temperature characteristics, device HJPT1000 cannot operate under environmental temperatures TA≥140℃.

6. Although this device's power supply and outputs can adapt long line transmission, its input cannot accept long line signals; therefore it is recommended that users do not exceed50cm for transmission lines from PT1000 to device input.

Key words:

development ,interference

recommend News

Looking for quality suppliers to create a better future together

Shaanxi Hangjing Microelectronics Co., Ltd. was established in 2001 and is located in the new industrial park

2024-07-09

A domestically produced LVDT/RVDT conditioner that replaces AD698

HJG698 is an LVDT/RVDT excitation demodulator designed using thick film integrated process

2024-04-01

A sensor processing circuit specifically designed for thermoresistor PT1000.

With the development of the Internet of Things era, sensors, as an important component

2024-01-11

Hangjing has announced the upgrade and optimization of domestically produced products.

In the spirit of being responsible to customers and continuous improvementction.

2023-08-12

Internal Appraisal Public Account

On April 2, 2022, Shaanxi Hangjing Microelectronics Co., Ltd. organized a product design confirmation meeting

2023-06-12